Even the highest-end displays on the market share an uncomfortable truth: no LED wall reaches its full visual potential straight out of the box. While advanced engineering plays a major role, true visual realism is achieved through calibration. Without precise adjustment, factors such as diode aging or variations between production batches can compromise even a premium installation.

Calibration is the process that allows LED technology to perform as a unified system. It goes far beyond powering on the hardware. The goal is to control color accuracy, stabilize brightness, and achieve consistent uniformity across the entire surface. In environments where precision matters (such as broadcast studios, esports venues, or houses of worship) an uncalibrated panel quickly becomes a visual distraction.

Whether the objective is to elevate a retail environment or preserve brand accuracy during live productions, technical optimization is what separates basic setups from professional LED solutions. In this article, we explain how proper calibration transforms individual LED devices into a cohesive visual experience that protects your investment and enhances long-term performance.

Our professional installation team ensures that your LED display is properly integrated and optimized for maximum performance.

Why Calibration Is Essential for LED Screen Performance

Understanding LED wall installation for beginners, and in a large-format system, is only the starting point. For LED screens to deliver reliable results, technical accuracy must be aligned with how the human eye perceives images. Calibration bridges that gap, ensuring that hardware performance meets professional standards.

Below are the key reasons why this process is not optional.

Human Eyes Notice Imperfections Before Technology Does

The human eye is highly sensitive to variations in brightness and color. Even when technical specifications appear correct, minor inconsistencies between modules can disrupt visual continuity. LED walls are designed to function as a single digital surface; without proper calibration, viewers stop engaging with the content and instead notice seams, patches, or tonal shifts.

Consistent Color and Brightness Improve Brand and Production Quality

In broadcast, retail, and virtual production environments, consistency communicates professionalism. A logo that appears slightly different from one LED display panel to another weakens brand identity. In production settings, inconsistent visuals complicate camera work and post-production. Calibration ensures that colors remain accurate and brightness levels stay uniform from start to finish.

Calibration Protects Your Investment

Calibration is also a form of preventative maintenance. By evenly distributing brightness levels, it prevents certain LED panels from compensating for others, reducing thermal and electrical stress. This balanced operation minimizes pixel degradation and extends the lifespan of your LED screens, protecting your investment over time.

Understanding the Core Elements of LED Calibration

Achieving professional-grade image quality requires more than subjective adjustments. It demands, for example, achieving optimal viewing angles with LED display placement. Proper calibration is rooted in color science and light behavior, focusing on three core elements that define whether an LED wall simply looks acceptable or performs at a professional level.

Let’s break down the technical components that turn hardware into a precision tool.

Color Accuracy and White Balance

The primary objective of calibration is stable, predictable color reproduction. By fine-tuning white balance and managing the color gamut, calibration ensures that whites remain neutral and that skin tones and brand colors appear exactly as intended. This guarantees that what is created during content production is faithfully reproduced on the LED display.

Brightness Levels for Different Environments

Not all environments require the same light output. A controlled studio setup demands different brightness levels than a storefront exposed to daylight. Calibration aligns brightness with ambient conditions, preventing washed-out visuals or camera overexposure. Proper adjustment preserves contrast, detail, and overall image depth.

Uniformity Across All Panels

Uniformity is one of the most technically demanding aspects of calibration. Even panels from the same model can vary slightly due to manufacturing tolerances. Pixel-level or module-level calibration ensures consistent luminance and color across every LED panel. Eliminating visible seams or brightness patches is essential for broadcast and virtual production environments.

Practical Tips for Calibrating LED Displays Effectively

Professional results depend not only on the right tools but also on proper methodology. Poor calibration can introduce new visual issues rather than resolve them. Following proven best practices ensures reliable outcomes.

Start With a Neutral Calibration Environment

Ambient light directly affects perception. Calibration should be performed in a neutral environment with consistent lighting and no color contamination. Natural light changes (such as passing clouds or sunset) can distort reference points and invalidate adjustments.

Use Professional Calibration Patterns and Test Images

Avoid using random content for adjustments. Professional test patterns, including grayscale bars, gradient ramps, and solid color fields, allow technicians to identify color shifts, brightness inconsistencies, and transition issues across the entire LED wall.

Balance Brightness Instead of Maximizing It

Running LED screens at full brightness may seem appealing, but it accelerates wear and reduces visual comfort. Balanced brightness delivers better contrast, deeper blacks, and longer component life. Calibration should prioritize clarity and longevity over raw output.

Evaluate the Wall From Multiple Distances

Validation should include both close-range inspection and evaluation from the intended viewing distance. Minor inconsistencies that appear insignificant up close can become noticeable artifacts when viewed by an audience or camera.

When to Recalibrate Your LED Video Wall

Calibration is not a one-time task. Over time, usage and environmental conditions affect performance. Knowing when to recalibrate ensures that LED video walls maintain a consistent, high-quality appearance throughout their lifecycle.

After Transport or Physical Handling

Rental systems and touring installations are subject to constant movement. Assembly, disassembly, and transport vibrations can affect alignment and connections. Recalibration after installation ensures uniformity and prevents visible seams between panels.

When Panels Are Replaced or Added

LED panels from different production batches rarely match perfectly. When replacing or expanding a system, recalibration is essential to blend new panels seamlessly with existing ones, preserving visual continuity.

Seasonal or Environmental Changes

Temperature, humidity, and dust affect LED performance over time. Systems calibrated for controlled interiors may shift when conditions change. Periodic recalibration helps maintain consistent results regardless of environmental challenges.

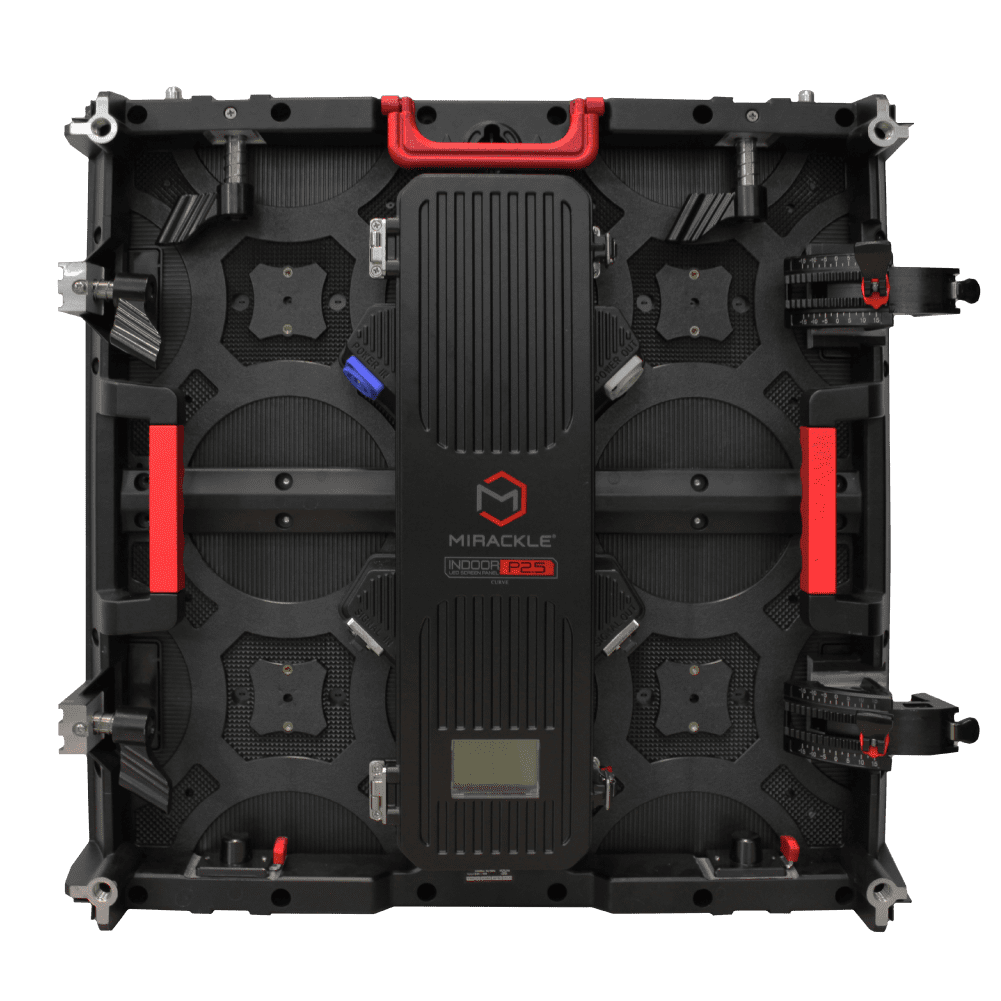

Mirackle LED Technology: Precision Makes the Difference

In today’s market, the difference between a standard setup and a premium visualization system lies in precision. At Mirackle, LED technology is engineered with calibration in mind from the start. We design visual systems that maintain performance consistency throughout their operational lifespan.

Proper Calibration: Keep Your LED Wall Display Looking New for Years

Longevity depends not only on build quality but also on intelligent configuration. Regular calibration prevents component stress, slows diode aging, and preserves brightness balance. A properly maintained LED display continues to deliver sharp, vibrant visuals long after installation.

Why Manufacturers Like Mirackle Lead in Calibration Standards

Our leadership is built on rigorous technical standards. Calibration is integrated into our production process, not treated as an afterthought. Every LED display panel undergoes precise adjustment before leaving our facility, ensuring optimal performance from day one.

Strict binning processes guarantee consistent color response across all diodes, while optimized drivers stabilize luminance and compensate for thermal variations during extended operation. Multiple stages of digital and visual inspection ensure uniformity across every section of the screen.

The result is a system designed to perform reliably, consistently, and professionally…Without compromise.